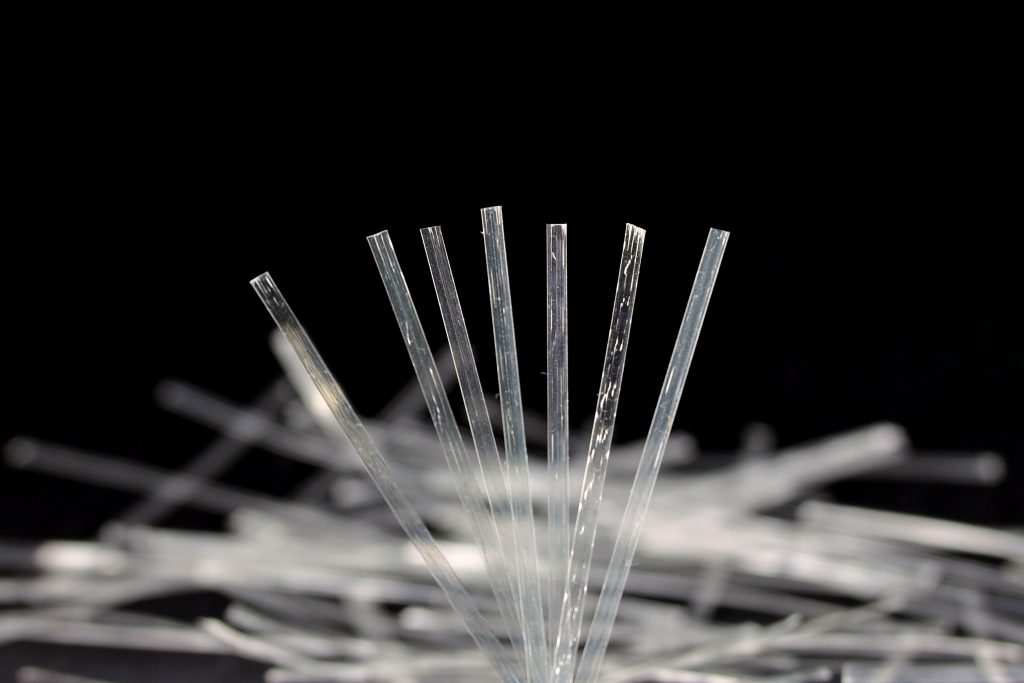

- ConFib FB Micro Fiber

- ConFib MF Micro Fiber

- ConFib Macro-48

Product Description

ConFib FB Microfibers are engineered from 100% virgin polypropylene, precisely designed in a micro-fibrillated form to enhance concrete performance. Through this, effectively minimize the risk of cracking due to plastic shrinkage and settlement by creating a network system in concrete. These fibers go a step further, enhancing the overall durability and toughness of the concrete, making it a more valid construction material.

ConFib FB Microfibers are engineered with concrete in mind, making them alkali resistant, non-absorptive, and entirely non-corrosive.

Compliance and Certifications

- European Standard EN 14889-2:2006 Fibres for Concrete Part 2: Class Ia

- ASTM C1116 / C1116M, Standard Specification for Fiber-Reinforced Concrete, Type III Synthetic Fiber-Reinforced Concrete

Advantages

- Supports mechanical behaviour of concrete

- Minimizes shrinkage and settlement cracks.

- Increases impact and abrasion resistance.

- Increases durability of concrete.

- Reduces permeability and increases freeze-thaw resistance.

- Increases fatigue strength and extends concrete service life.

- Increases toughness of concrete and makes it flexible.

- Increases cohesion and reduces segregation.

Aplication Areas

- Slabs on ground

- Shotcrete applications

- Plaster, mortar and screed applications

- Precast and prefabric applications

- Concrete roads and under rail concrete

- Coastal structures

Dosage & Uses

Dosage ratio may vary according to applications. Standard dosage ratio of Confib FB micro fibers are 0.9 kg/m3 of concrete in general applications.

Confib MF micro fibers may be added to concrete at batching plant or in truck mixer on construction site. The concrete should be mixed for 5 minutes after the addition of the last package of fibers to ensure uniform distribution.

Physical Properties

Material | %100 virgin polypropylene |

Standard | ASTM C1116/C1116M, EN 14889-2 |

Specific gravity | 0,91 g/cm3 |

Cut Length | 6-12-19-25 mm |

Tensile Strength | 400 MPa |

Modulus of Elasticity | 7 GPa |

Alkali, acid and salt resistance | Excellent |

Water Absorption | None |

Melting Point | 140 °C |

Packing

Confib MF synthetic microfibers are shipped in water-soluble packages ready to be added directly to the mixer or concrete batching plant. 0.6 to 2 kg water-soluble packages and 25 kg boxes are available. Customized packing configurations are available upon request.

Product Description

Introducing ConFib MF Microfibers, the cutting-edge synthetic concrete reinforcement solution! ConFib MF Microfibers are engineered from 100% virgin polypropylene, precisely designed in a micro-monofilament form to enhance concrete performance. Through this, effectively minimize the risk of cracking due to plastic shrinkage and settlement. These fibers go a step further, enhancing the overall durability and toughness of the concrete, making it a more valid construction material.

With over 50 million individual microfibers packed into every 600 gr/m³ application, ConFib MF Microfibers engineered with concrete in mind, making them alkali resistant, non-absorptive, and entirely non-corrosive.

Compliance and Certifications

- European Standard EN 14889-2:2006 Fibres for Concrete Part 2: Class Ia

- ASTM C1116 / C1116M, Standard Specification for Fiber-Reinforced Concrete, Type III Synthetic Fiber-Reinforced Concrete

Advantages

- Minimizes shrinkage and settlement cracks.

- Increases impact and abrasion resistance.

- Increases durability of concrete

- Reduces permeability and increases freeze-thaw resistance.

- Increases fatigue strength and extends concrete service life.

- Increases toughness of concrete and makes it flexible

- Reduces rebound in shotcrete applications

- It solves the problems such as cracking, abrasion and chipping in dusty product applications (repair mortar, ready-made plaster, screed, surface hardener, etc.) and increases the surface resistance of the applied mortar.

Dosage & Uses

Dosage ratio may vary according to applications. Standard dosage ratio of Confib MF micro fibers are between 0.6 – 0.9 kg/m3 of concrete in general applications. For increased fire resistance, dosage of 2 kg/m³ is generally recommended.

Confib MF micro fibers may be added to concrete at batching plant or in truck mixer on construction site. The concrete should be mixed for 5 minutes after the addition of the last package of fibers to ensure uniform distribution.

Aplication Areas

- Slabs on ground

- Shotcrete applications

- Plaster, mortar and screed applications

- Precast and prefabric applications

- Cement-based composites

- Concrete roads and under rail concrete

- Coastal structures

Packing

Confib MF synthetic microfibers are shipped in water-soluble packages ready to be added directly to the mixer or concrete batching plant. 0.6 to 2 kg water-soluble packages and 25 kg boxes are available. Custimized packing configuraitons are available upon request.

Material | %100 virgin polypropylene |

Standard | ASTM C1116/C1116M, EN 14889-2 |

Specifit gravity | 0,91 g/cm3 |

Cut Length | 6-12-19-25 mm |

Tensile Strength | 360 MPa |

Modulus of Elasticity | 3-3,5 GPa |

Alkali, acid and salt resistance | Excellent |

Water Absorption | None |

Melting Point | 140 °C |

Product Description

ConFib Macro-48 is engineered from 100% virgin polypropylene, precisely designed to enhance concrete performance as primary reinforcement. Through this, Macro-48 can be used instead of steel mesh and steel fiber within concrete. Besides, effectively minimize the risk of cracking due to plastic shrinkage and settlement by creating a network system in concrete. These fibers go a step further, enhancing the overall durability and toughness of the concrete, making it a more valid construction material.

ConFib Macro-48 is engineered with concrete in mind, making them alkali resistant, non-absorptive, and entirely non-corrosive.

Compliance and Certifications

- European Standard EN 14889-2:2006 Fibres for Concrete Part 2: Class Ia

- ASTM C1116 / C1116M, Standard Specification for Fiber-Reinforced Concrete, Type III Synthetic Fiber-Reinforced Concrete

Advantages

- Can be used as primary reinforcement in concrete instead of steel mesh and steel wires.

- Saves money through reduction of application time and labor cost.

- Improves jobsite safety by eliminating the handling of steel mesh and rebar.

- Provides superior crack control and minimizes shrinkage and settlement cracks.

- Increases durability of concrete and extends concrete service life.

- Reduces permeability and increases freeze-thaw resistance.

- Reduces rebound problem on shotcrete applications.

Aplication Areas

- Slabs on ground and industrial floors

- Shotcrete applications

- Composite steel floor deck

- Precast and prefabric applications

- Concrete roads and under rail concrete

- Coastal structures

Dosage & Uses

Standard recommended dosage rate of ConFib Macro-48 is between 2-6 kg/m3 of concrete. The dosage rate of Macro-48 may vary according to the area and application. . It is recommended that, user should consult to the authorities and use professional services to determine the suitability of the product in any project or application before commercial use.

Confib Macro-48 may be added to concrete at batching plant or in truck mixer on construction site. Each packet should be added to the mixer at 20-30 second intervals. The concrete should be mixed for 5 minutes after the addition of the last package of fibers to ensure uniform distribution.

Physical Properties

Material | %100 virgin polypropylene |

Standard | ASTM C1116/C1116M, EN 14889-2 |

Specific gravity | 0,91 g/cm3 |

Cut Length | 48 MM |

Tensile Strength | 600 MPa |

Modulus of Elasticity | 10 GPa |

Alkali, acid and salt resistance | Excellent |

Water Absorption | None |

Melting Point | 140 °C |

Packing

ConFib Macro-48 is available in 1,5 kg water-soluble packages. Customized packing configurations are available upon request.

Click here to download the SDS document for the fibers.

Fiber Types According to ASTM C1116 & EN 14889-2

ASTM C1116 – Standard Specification for Fiber-Reinforced Concrete

According to ASTM C1116, fibers used in fiber-reinforced concrete are classified into four main types:

- Type I – Steel Fiber

- Type II – Glass Fiber

- Type III – Synthetic Fiber

- Type IV – Natural Fiber

Steel fibers made from carbon or stainless steel, typically used to improve the structural performance, toughness, and crack resistance of concrete.

Alkali-resistant glass fibers designed to resist the alkaline environment of concrete. These fibers are mainly used for controlling plastic shrinkage and temperature cracking, and in some cases, for structural reinforcement.

Synthetic fibers produced from polymers such as polypropylene, polyethylene, nylon, or polyester. They are used to control plastic shrinkage cracking, improve impact resistance, and enhance durability.

Fibers derived from natural sources such as cellulose, sisal, jute, or coconut. These are primarily used for controlling plastic shrinkage and temperature cracking, and are less common in structural applications.

Definitions of Microfibers and Macrofibers According to ASTM C1116 EN 14889-2

- Microfibers (Micro-Fibers):

- Macrofibers (Macro-Fibers):

According to ASTM C1116 & EN 14889-2, microfibers are defined as fibers with a nominal diameter less than 0.3 mm (300 microns) and a length typically less than 19 mm. Microfibers are primarily intended to control plastic shrinkage cracking and to reduce settlement cracking in concrete. They are generally not considered to provide significant post-crack load-carrying capacity.

Macrofibers, as defined by ASTM C1116 & EN 14889-2, are fibers with a nominal diameter equal to or greater than 0.3 mm (300 microns) and a length typically greater than 19 mm. Macrofibers are designed to provide post-crack load-carrying capacity, improve toughness, and enhance the structural performance of concrete. They are used as an alternative or supplement to traditional steel reinforcement in certain applications.

Key Terminology in Fiber-Reinforced Concrete

Aspect Ratio:

The ratio of the fiber’s length to its equivalent diameter. Mathematically, a higher aspect ratio generally enhances the fiber’s effectiveness in crack control and mechanical performance.

“Aspect Ratio: Fiber Length / Fiber Diameter”

Equivalent Diameter of a Fiber:

The diameter of a hypothetical circular fiber having the same cross-sectional area as the actual (possibly non-circular) fiber. It is used to standardize comparisons between different fiber shapes.

Monofilament Fibers:

Single, continuous, and fine fibers, typically made from synthetic materials such as polypropylene. They are primarily used to control plastic shrinkage cracking in concrete.

Equivalent Flexural Strength:

A parameter defined by ASTM C1609 that measures the post-crack load-carrying capacity of fiber-reinforced concrete. It is calculated based on the average load sustained by the specimen at specified deflections during a flexural test.

Equivalent Flexural Ratio:

The ratio of the equivalent flexural strength to the first-crack flexural strength of the concrete. It indicates the post-crack performance provided by the fibers.

Flexural Strength:

The ability of concrete to resist failure in bending. Fiber reinforcement can enhance the flexural strength of concrete.

Toughness:

The energy absorption capacity of concrete after cracking, representing its ability to withstand deformation and dissipate energy. Fibers significantly improve the toughness of concrete, reducing the risk of sudden failure.

Crack:

A separation or fissure in concrete resulting from loading, shrinkage, or other effects. Fibers help delay crack formation and limit crack width.

Denier:

A unit of measurement for the linear mass density of fibers, defined as the mass in grams per 9,000 meters of fiber.

“Denier: Mass in grams / 9,000 meters”

Ductility:

The capacity of concrete to undergo significant deformation before failure. Fiber reinforcement increases the ductility of concrete, making it less brittle.

Number of Fibers:

The total number of individual fibers present in a given volume (typically 1 m³) of concrete. This depends on the fiber dimensions and dosage.

Fiber Dosage Rate:

The amount of fiber added to the concrete mix, usually expressed in kilograms per cubic meter (kg/m³).

Fiber Volume Fraction:

The volumetric proportion of fibers within the concrete mix.

“Fiber Volume Fraction: Volume of Fibers / Total Volume of Concrete”

It is typically expressed as a percentage (%).